Female Welding Stud Cd Weld Standoffs For DJ Audio Sheet

Female Welding Stud Cd Weld Standoffs For DJ Audio Sheet

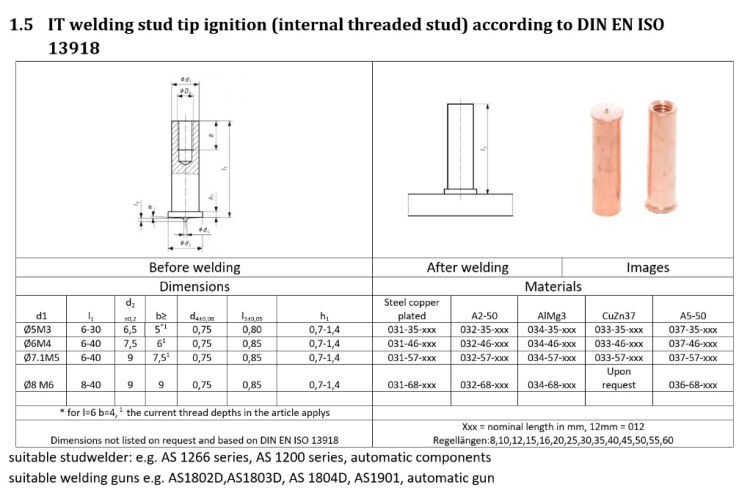

Internal Threaded Welding Studs CD Welding Standoffs(Female Welding Stud Cd Weld Standoffs)are specialty fasteners designed for capacitor discharge (CD) stud welding on thin sheet metal surfaces. These CD Welding Standoffs are internally threaded (female) and are used to form secure joints in thin sheet metal without the need for drilling holes, screws, or nuts.The CD Welding process is a fast, low-heat method that is ideal for preventing distortion or warping of thin materials. Capacitor and short cycle welders or CNC automatic stud welders and PLC semi-automatic stud welders are used for welding. These CD Welding Standoffs are commonly used in electronic, automotive and audio equipment where lightweight, durable and aesthetically molded mounting solutions are critical.

Applications:

DJ Audio Equipment:

Used in DJ audio systems and professional audio equipment to mount circuit boards, speakers and other electronic components to metal chassis or enclosures without damaging or warping the material. Below is a picture of a customer feedback application for a DJ table top. This stud was welded using our professional CNC automatic stud welder for a beautiful molding.

Electronic and Electrical Panels:

Use these standoffs in electrical cabinets, audio control units, and power supply housings where fragile components need to be mounted reliably. You can choose a CNC stud welder to weld them.

Automotive:

Apply to automotive electronics to secure wiring harnesses, control modules and other components to the body or panel without the need for extra holes or mechanical fasteners. You can choose CNC stud welder and short cycle welder for welding.

Home Appliances:

Used in the assembly of home audio systems, speakers and sound equipment to provide a secure base for mounting circuit boards or other hardware inside a metal enclosure. Can choose capacitor welder or PLC semi-automatic welder for welding.

Features

Capacitive Discharge (CD) Soldering:

Uses CD stud welding technology to quickly weld standoffs to the surface of thin sheet metal (as thin as 0.5 mm) without warping or overheating damage.

Internal Threads (Female):

Designed with internal threads to provide a reliable, convenient attachment point for screws or bolts, making them suitable for mounting a variety of components.

No Drilling Required:

CD welded standoffs eliminate the need for drilling or the use of screws and nuts, preserving the structural integrity of the sheet metal while ensuring a strong connection.

Corrosion-resistant materials:

Available in stainless steel and aluminum, copper-plated and other materials that are highly corrosion-resistant and suitable for environments exposed to moisture, high temperatures or other harsh conditions.

Fast and efficient installation:

Paired with a stud welder, CD weld standoffs can be welded in milliseconds, providing a fast and efficient method of assembling parts without lengthy preparation.

Precision Welding:

Using fully automated CNC welding ensures that the standoffs are precisely positioned on the metal surface, which is critical in applications where space is limited or part alignment is critical.